Being built right now.

Fingerboard Refinements:

Fingerboard Refinements:

I planed and sanded the radius, the string gauge compensation and relief offset into the fingerboard. The compensation is there to give each string a different relief as the different gauges have different wave apexes. The offset as I call it, is my best descriptive word for the part of the fingerboard the truss rod can not act upon. Both are something many luthiers either ignore or don't even know exists, very few add compensation for the difference in string gauges, and some don't continue the dip of the relief to the very end of the fingerboard, but instead take the easy way out by adding "drop off", which is exactly what it sounds like, as the fingerboard either continues straight on or even dips down towards the end, instead of raising back up and following the arch of the strings wave. Doing both, assures lowest possible action throughout the fingerboard for all strings, and more comfortable playing, which is more important on a bass because of the thick strings.

I had some extra length on the base of the neck I had to trim off, and also on the fingerboard, and since I don't like to have the fingerboard end straight on a curvy guitar, I gave it some thought to how I should curve it. And since this bass has a theme, the "spirangle", the decision to carve one in the end of the fingerboard was easy:

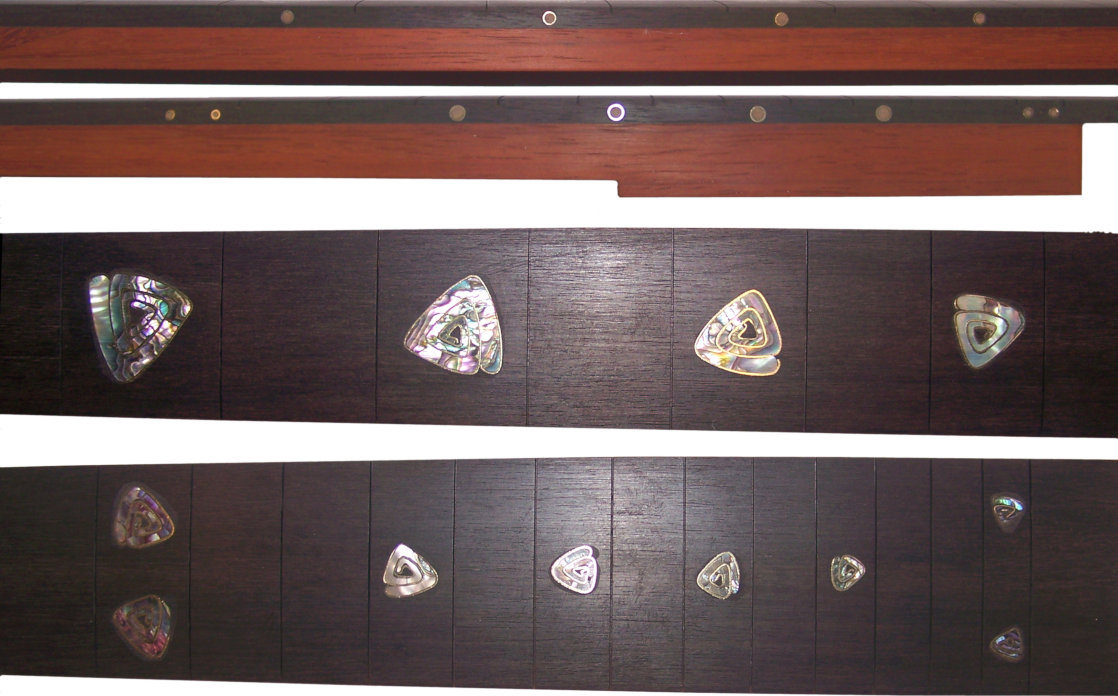

Dot inlays on the front of a fingerboard are so common, that I would rather stay away from them, and again to stay with a theme, I made those spirangles too. Those were terribly difficult, as the saw blade I used cut a slot just wide enough to fit the gauge of the brass I used for the headstock logo, and when making deep cuts into abalone, the saw blade will bind and it wants to break, and does so along the lines separating the different colors. It did just that more than a few times. If glued back together with cyanoacrylate it won't show, but doing that accurately, as in without offset, is not easy. I had to get the brass into those slots, and squeezing it in doesn't work, as it will not conform. I had to bend the brass very accurately to fit in the saw cuts, otherwise risk more breakage I can imagine that tools for such tight bends exist, but I don't have them, and so had to wing it. That wasn't easy either, as some bends were very tight, and being spirals there's less room for tools, and the smaller the inlay the harder it got. Each inlay took between 3 to 8 hours to complete.

The inlays are green abalone accept for the two on the twelfth fret which are red paua abalone, and the two on the 24th fret are blue paua abalone. The side marker dots were much easier as I used round brass tubing filled with maple.

Body Work Part 2:

Body Work Part 2:

With the fingerboard inlays out of the way, and finalizing the drawing of the body, I go back to working on it. I want to put a slight arch in the top, and partially recess the controls, so that they don't look odd, being close to the top on one side, and high on the other. and there are more controls than most instruments on this bass. If it can have a wide range of tone, I want it's future owner to have access to them. Although some people frown on a lot of controls, especially in a live setting, they are indispensable in the studio. To lessen control overload for live playing, they are laid out in a sensible order, with one section for pickup selection, and an EQ section, with a knob for each band, not 3 bands with two controls, where one is a stacked pot hard to see or get a grip on. I will have a detailed control description with the publication of the finished instrument, as I will tweak the EQ circuit based on the sound of the instrument when everything else is finished.

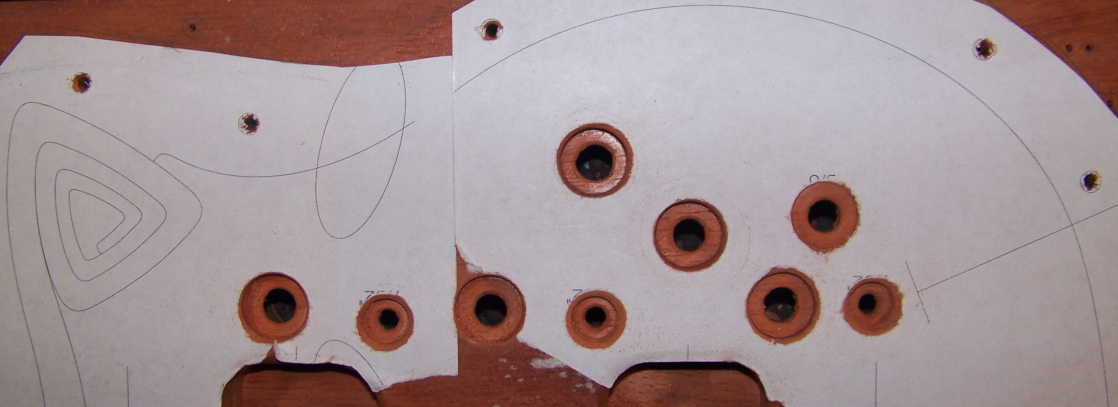

From the back looking into the control cavity, I had to either rout it in different depths for some controls or just cut the whole cavity at one size and adjust a few of the holes. For that I used some of the maple I had already at the right thickness. Once the copper shielding is in, they won't be seen.

After the control mounting holes, cavity, and pickup routs, I routed the body to shape. Heres the top:

Heres the bottom:

Flip the page to see more scroll carving.