ES 3350?

ES 3350?

Don't You mean ES 335 as in "Gibson ES 335", where the ES stands for "Electric Spanish"?

Well no, I mean ES 3350 as in "Extra special", so special in fact it deserved an extra decimal!

It all started when a client of mine offered me a Reid and Son's (RAS) kit guitar as partial payment for some work I had done for him, and I decided to take it so my apprentice Dan had something to practice on. He actually thought I was going to let him put it together as per instructions, with everything supplied with it. Little did he know, that wouldn't fly here at  .

.

Here is what we started with, it is a 12 string RAS SES 30 (that is what they call it), but since we already tore into it before I could take some "before" pictures, this first set of shots are from a six string version I found on the interweb:

Check out the cheap plastic binding:

Even worse, cheap plastic fret marker inlays (poor-ins, not inlays):

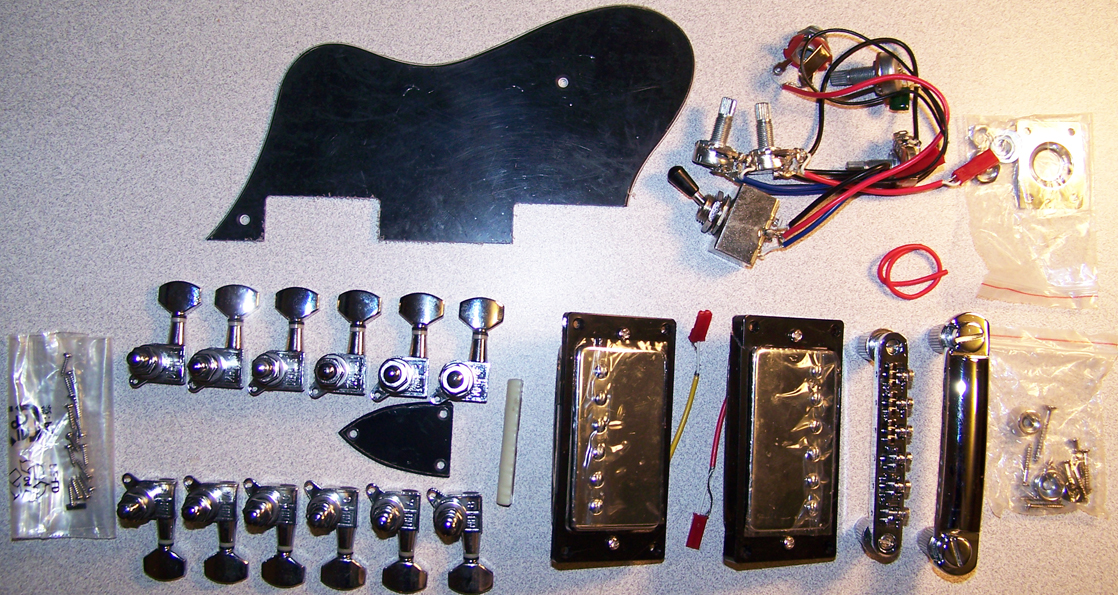

And here is the stuff it came with:

From a manufacturing view it is no worse than many other similar Chinese made instruments like some Epiphone's or one of the many ES 335 knockoffs, I know, I have worked on a lot of them, and don't let brand names fool you! You would be surprised at what you may find if you tear yours apart.

The Tear Down:

The Tear Down:

To start I had Dan plug up the holes for the tuners because the headstock was ugly and crooked, the holes were to big for the tuners, and the angle of the strings to the nut were so extreme that it would cause sideways nut wear, and tuning problems down the road. We would rework the entire headstock later, with a new much better design. Here is what that looks like for now:

Next I had Dan sand the top and back of the headstock down, so it would not end up to thick after adding wood overlays to it, besides the surfaces were anything but flat. He did not get far with any work, because his wife gave birth to a happy baby boy, and had to put the apprenticeship aside for the time being. We don't know if his son was bouncing, because we were afraid of dropping him to find out, and did not try to. needless to say the guitar laid around for over a month, and Dan called to say that he couldn't continue to apprentice, as he was moving to Texas. I decided to work on it myself in order to get it done, so it could be sold.

I proceeded in removing the cheap plastic binding that surrounded the fingerboard, body and f-holes, drilled and chiseled out the fret marker inlays and removed the cheap (too soft) frets. I looked through my stash of materials, to come up with a new binding and inlay scheme. Here is what I found to be aesthetically pleasing:

Here we have some Macasar Ebony and maple veneers and a huge black lip pearl shell from a piece of jewelry I found for cheap at a thrift store. The Macasar Ebony looks almost Identical to the rosewood that the fingerboard is made of, and if I didn't tell you, you would most likely not see the difference. I only show a small piece in the picture, but I had some rather large pieces, that you will see later on the headstock, pick guard and various other places.