Wiring and assembly:

Wiring and assembly:

After all the harder work is done, the time comes to put the pieces together. below is what a good fit looks like, I can not show you how well the neck fits into the neck pocket, but it is almost as if the neck was poured in A well fitting neck to body connection is key to good note clarity and long sustain, and you will never see me using cardboard, used picks or other unsuitable crap for shims. On instruments I design and build, I never make bolt on necks.

The neck and bridge are in alignment now, but I also had to close off and re-drill the mounting screw holes for the neck pickup because they were out of whack:

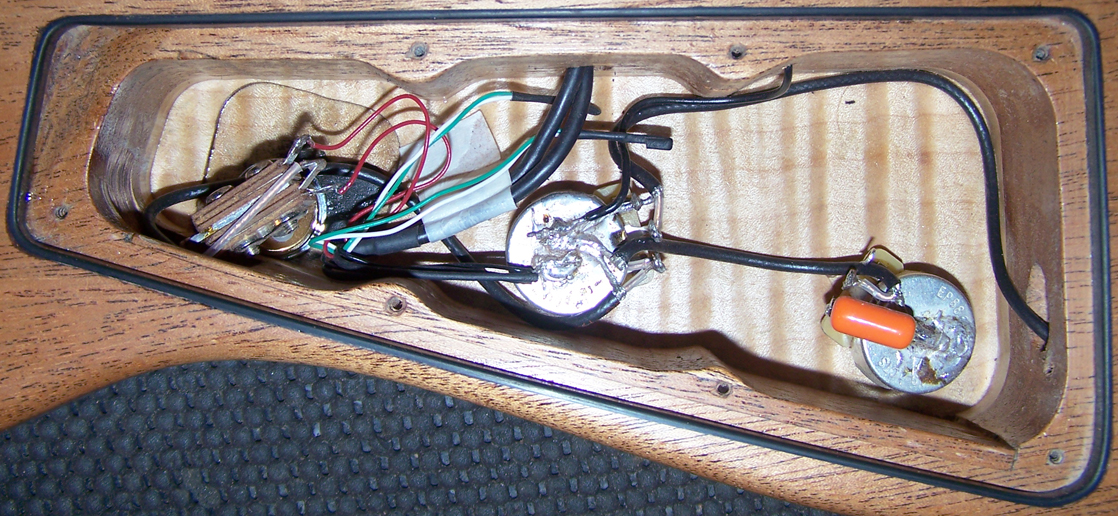

I failed to mention earlier that I had to close off and re-drill the mounting screw holes for the strap buttons and jack plate, and grafted some wood into the jack hole and re-drilled it too, to center them all. Most of it is barely visible, or not at all. I Mounted the tuners, popped the controls back in; wow how roomy!

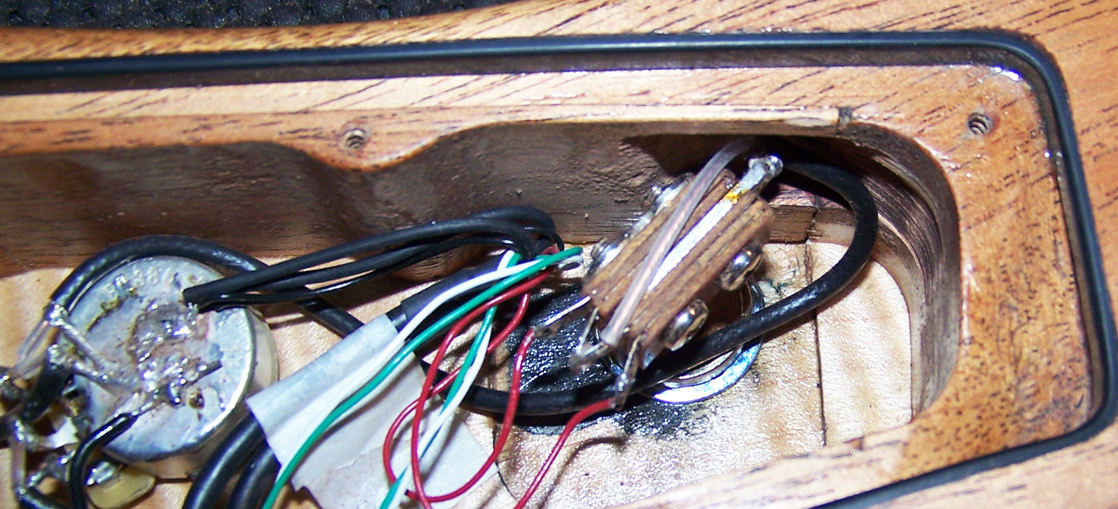

Time to wire it all back up, this time using military grade wire with double braided shielding and good connections throughout, with the pickups in magnetic as well as electrical phase. I could have spent the time to shield the whole cavity, but after some testing it proved to be unnecessary, and the circuit is noise free.

I made a recess to allow the pickup selector switch to be rotated to wherever Mr. X needed it for best use, and as you may be able to tell, it is not turned the same way it was originally.

There is a right and many wrong ways to wire in audio and other frequency related applications, and even major manufacturers often do not get it right. JLH most certainly did not. For me it is routine procedure.