Mr. X gets a break:

Mr. X gets a break:

Here is where my ranting about JLH's incompetence ends, and I explain what all I did to make the guitar a viable instrument, worth using. I know the previous chapters were full of harsh criticism, but it just upsets me when someone misrepresents themselves that much, and does not take responsibility for their actions. He is still doing business as usual, and his pool of victims is growing.

Mr. X asked me to do everything necessary to make the guitar play well, which was quite a bit, and would not be cheap. I knew that if I did just that, he would still not truly enjoy it still, as it was a heavy and uncomfortable beast, and decided to go beyond the call and rebuild the whole thing. I Quoted Mr. X a price for the work, and said I would throw in some extra, and write it off as work for my portfolio. At the time I needed more to show for, and after what he had been through, he deserved a break.

My work begins:

My work begins:

I started by disassembling the whole thing, and that was not routine as I had hoped for. The bridge string retainer, mounting hardware and neck bolt washers were jammed in tightly, and finish was applied afterwards, so they were essentially glued down. Of course I managed to get everything apart without causing any damage, and once everything was apart, I was faced with the question: Where to begin?

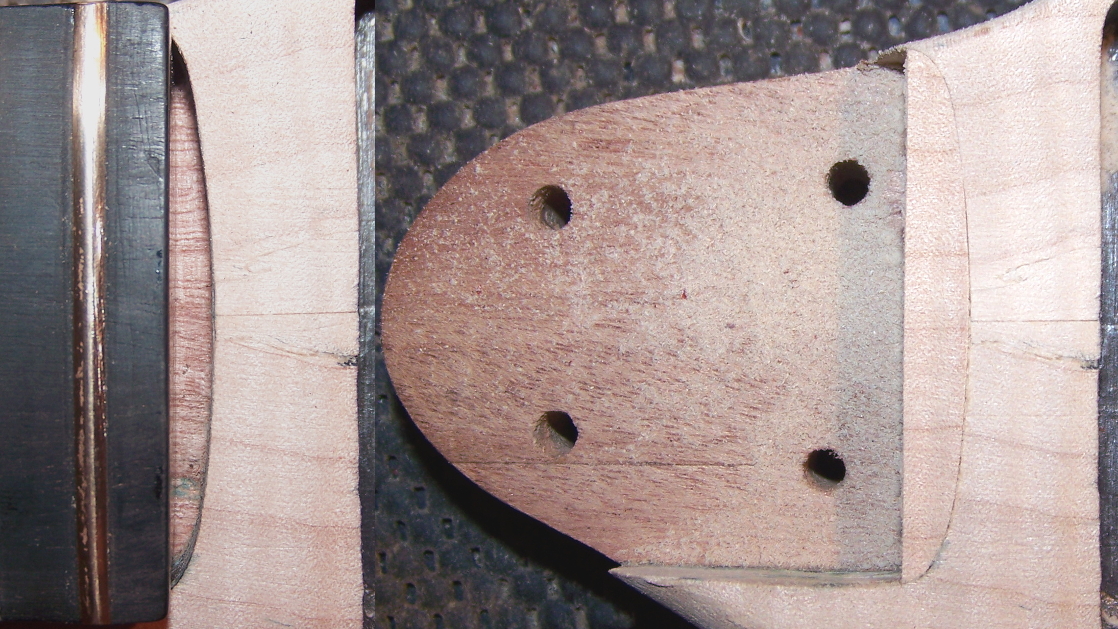

I decided to rebuild the neck pocket first, because it was off in all directions, and it was just the most important part in allowing the action and intonation to be set right. Without that everything else would be for naught. I knew I could not hide the repair completely, but it had to be done. I started with a mahogany shim to give the neck more angle to allow for a lower action:

Once I had that done, I removed the silly serial/model number block, so I could use the wood to close the gap at the neck end. Underneath it I found a chunk of wood that had broken out, and glued back in. Since I needed to see what I was doing there, I sanded down the top too:

The gap between the two pieces of maple was much more noticeable now. I cleaned up the serial number block, and carved it to fill the gap:

I also had to carve it further to follow the contour of the neck heel, but did not get a picture of that, it can be seen in other pictures later on though.