Fixing the bridge:

Fixing the bridge:

Time to tackle this beast, starting with the bridge. We want the bridge to not move so that the intonation stays true once set, but if the whammy bar is to stay functional, the screw thread saddles have to go. You can buy after market tail pieces that eliminate the tremolo, and string retainers to increase string angle off of the bridge for these guitars, as a matter of fact this one had one or the other at one point, because the screw holes and screws for something are still there. I did run those options by my client, but he wanted to be able to use the whammy, and a string retainer is just one more thing to contribute to tuning problems, so we ordered him some "Graph Tech" replacement saddles. The Graph Tech saddles are slick as all get go, and will make a great improvement to lessen tuning issues, and even out the string spacing too.

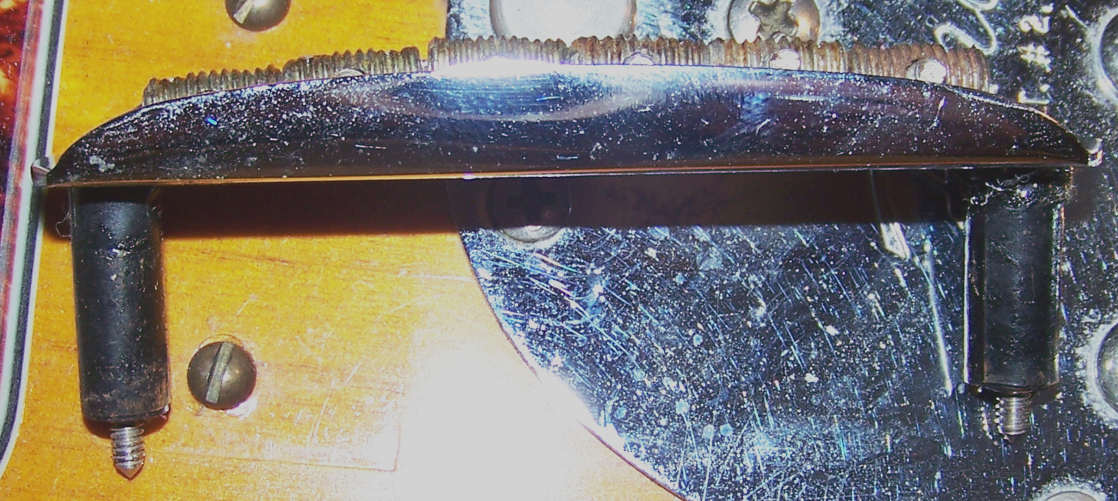

As you can see above, I am not the first one attempting to stabilize the bridge and prevent it from moving. If you look closer you may see that the bridge posts are wrapped with electrical tape which works OK, but I will use something that works better, brass tubing. I could not find any tubing for purchase that had the right inner and outer diameters, and so had to make the sleeves custom. Below you can see the bridge post with its height adjustment/pivot screw protruding, the raw material, and one almost finished sleeve that fits too snuggly around the bridge post, and into the post holders, which can now be called "post anchors".

I am sure the posts were a near perfect 1/4" before they were chromed, but after plating they are too large to fit into the sleeves I drilled at 1/4". No problem though, a 3/16" dowel with sandpaper adhered to it in a drill press was all that was needed to enlarge the holes until they slipped onto the posts without having to force them, yet not loose either.

Now of course I already have the sleeves just right to fit into the anchors in the body, but that in no way means that they are spaced accurately enough to accept the bridge as it is now. Sure enough it is too tight for comfort, so I had to sand the outsides of the sleeves down a bit too, once again, just enough, until it all fit without any wiggle. Here is the bridge installed and wiggle free, the Graph Tech saddles have not arrived yet.

Now to the silly spring loaded thing that is supposed to help the bridge stay centered, possibly even lift it up slightly so that the strings don't come off when the whammy is pushed down far. Either way, it sits in a hole that is drilled so far down that even with the spring, it didn't even touch the bridge. I was thinking of just leaving it out and handing it to the owner, but I realized that if it got lost, then some day down the road a "Collector" could flip out over it and possibly commit suicide, or even do something bad like commit murder over it! I decided to put a piece of wood dowel in the bottom of the hole, so it would push up snug against the bridge like it was supposed to in the first place.

As a side note, the pick guard was way off due to shrinkage, and in seeing how far off the holes for the springy thing and the bridge anchors were, I had to cut them out. Below is the doohickey as was, the doohickey posing with the dowel, and finally the doohickey sticking out of the hole proudly, ready to push up on the bridge enough to not bounce around and cause trouble.

An OK nut:

An OK nut:

Whenever someone needs a new nut for their guitar, I offer brass as one of the best choices, because it wears very slowly. This guitar did not need a new nut, but one day back when it did, who ever installed it knew what I do, although this one is the kind that used to be found in parts catalogs years ago and still is, just not as often anymore. It differs from the ones I make in a few ways. First of all it is made of a much softer alloy than the stock I use, as they were advertised as being "Made from instrument grade brass" AKA horn brass. Just another snake oil add campaign, because horns and guitars are completely different animals, and contrary to what you have most likely heard, the nut has nothing to do with the sound of the instrument at all, besides the sustain of open strings, and even that is negligible unless the nut is so soft that it actually acts as a dampener.

This nut has string slots that are spaced evenly string center to center, where I prefer to cut them centered evenly spaced string edge to edge, because it just feels right and more natural. Cut center to center makes the bottom strings feel crowded. Since the customer had no problem with it, it stayed as is.