Houston we have a problem:

As sometimes is the case when doing a job for a client, another job in need of attention rears its ugly head. In this case I was taking the strings off of a guitar in order to make a new nut for it, and I ran into a dilemma with the tuners.

This guitar is one of the many I have come across, where someone who does not know what they are doing, thinks they are qualified to call themselves a guitar repairman, tech or even a luthier, and makes major and potentially costly mistakes, including soliciting work in the profession, business cards and all.

The problems:

Besides the fact that I was asked to make a new nut for a guitar with a new nut, the expensive and high tech Sperzel tuners were messed with unnecessarily and in the wrong way.

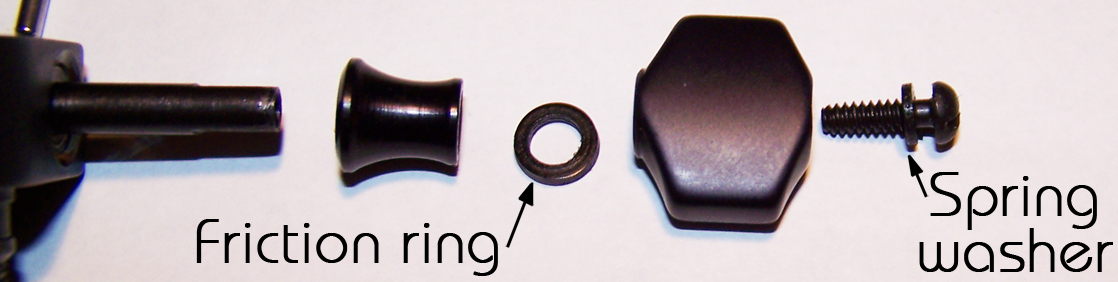

For starters the tuning knob screws that also function as tensioners were tightened with excessive force, threatening to cause damage to the gears and premature wear. Almost all modern tuners have tensioners. The screws should be tightened enough to remove all rotational slack of the tuning post, without making the tuners hard to turn. They have friction rings and spring washers to accomplish that, and are not made to be torqued down to hold the knobs on. Unless they are of poor design and materials, they will do so without coming loose and the knobs will not fall off.

Checking them and readjusting if necessary, is good practice whenever changing strings. It is often the case that the screws will feel way to loose, but the tension on the knob is just right, and that is OK.

The second and worse problem of the two is that the "non removable" locking knobs were removed by force, damaging the threads. It was not hard to tell that something was wrong, as it was really hard to turn the knobs in any direction, and the "A" string could not be locked down at all and slipped right out, as the locking pin was missing.

On early versions of Sperzel tuners it was possible to unscrew the locking knobs all the way and take them out, where the locking pin's would fall out and possibly get lost. By press fitting the knobs past their threads onto the gear (loose enough to still be turned), the newer ones do not come apart, unless forced with considerable strength.

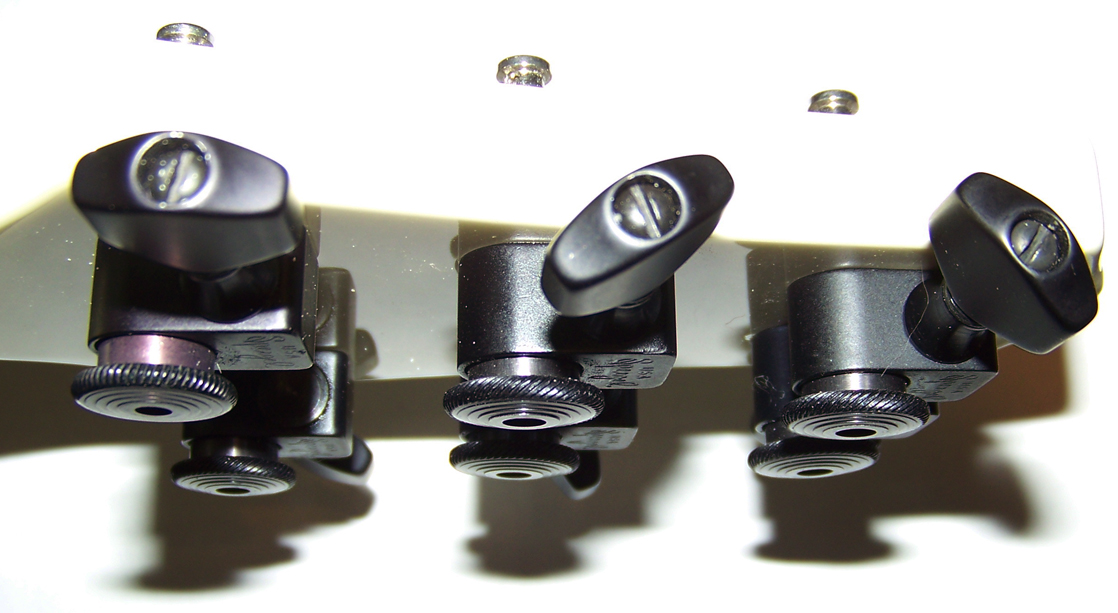

Here is a view of the tuners, notice how the knurled locking knobs are all at different heights even though there are no strings installed and they are all tightened as far as they go:

The repairs:

Before I even continued to loosen the strings, I adjusted the tuning knob screws to proper tension, then I took off all of the strings having to risk breaking a few of the locking knobs as they would not loosen without using a lot of force. Luckily they all came loose without breaking. I re-cut all of the threads, and made a new pin to replace the missing one. I just happened to have some fitting round stock to do so. Here is what I mean, first the lock knob threads:

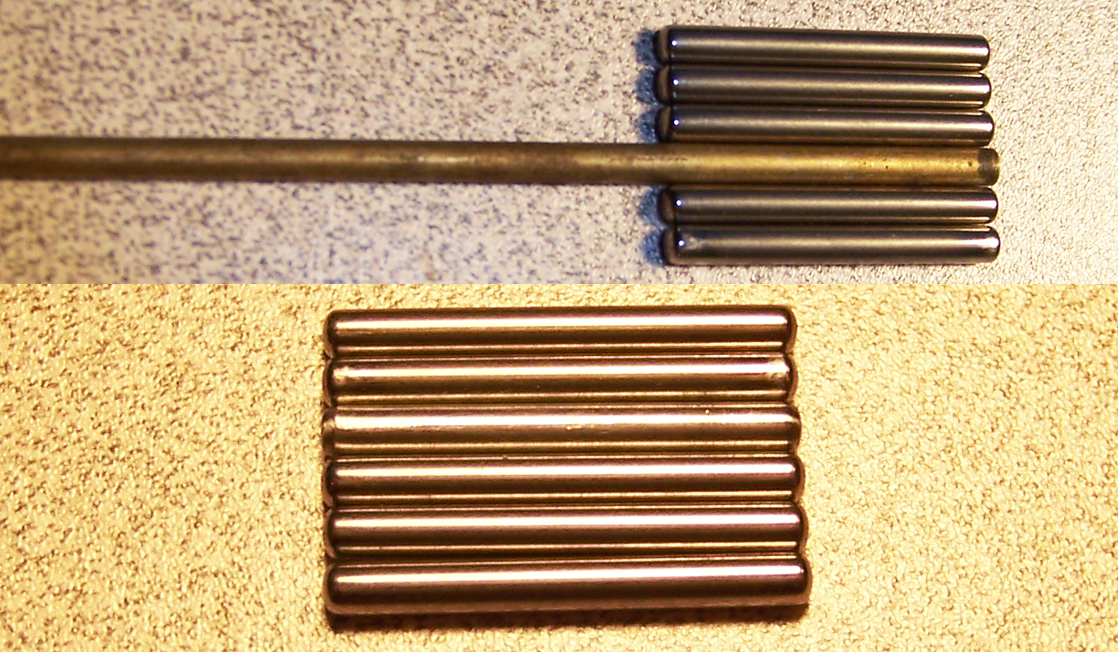

Next the stock and the pin I made from it. Although it looks like brass, it is steel, with a light coating, that was removed during polishing In the picture with all six pins, you have to look really close to tell that it is the 3rd. one from the top:

At this point I started to make the new string nut for the guitar, which is what I was asked to do in the first place. You can read up on that and see the results here (the white Carvin).

After making the nut (Rough part) it was time to see how well the tuners locked, as making accurate string grooves in the nut requires the strings to be on the guitar and up to tension. Sperzel documentation specifically notes to make them thumb tight, in other words not to crank them down like an ox or with the use of wrenches.

After all was said and done, the tuners worked as they were designed to, with the slight difference that they were like earlier versions, as one could undo the locking knobs all the way. As long as care is taken not to do that without keeping track of the pins, there will be no future problems.