Just a pick guard?

This is a 1968 Kustom K 200 D bass, one of only 200 made, and the "200" may be the reason for the model, but then maybe not, who knows? It is built in similar fashion to a Rickenbacker semi-hollow body with a bolt on, not a through neck. To me it sounds much like a Höffner Violin bass.

The pick guard was cracked in a few places, as it had dried out and shrank over the years, and the electronics also showed signs of corrosion, and it needed a setup. Those were the reasons the bass was brought to me, but it turned out that it had a few other problems I will get into later. Here is a closer view of what was left of the original pick guard, and a makeshift piece holding the output jack:

The owner of this rare bird, had already purchased a large sheet of material for the new pick guard, and I discounted him for the rest, so I have some on hand if You need one too.

Making the pick guard

First I traced what was left of the old pick guard, and then I filled in the blanks from photographs I found on line, and all of those were cracked too, but without missing sections. I cut out the new one, and shaped it with a few minor differences from the original: I added a radius, and smoothed out the edge much finer than the original. It may be hard to see in this next picture, but if You could feel it, You would know what I mean.

Of course I cleaned up the electronics before I attached the new guard, here is one of them "before" and "after" pictures we are so used to from the diet pill commercials:

Yes, I also cleaned all the gunk n' stuff out from under the old pick guard, including the rest of the instrument too while I was at it, chemical and scratch free of course, like so:

But wait, there's more!

When I tried to put the strings that the owner supplied on (Nylon wound Roto Sound's) the G and D did not fit in the tail piece, and the A and G did not fit in the nut. They were not a heavy gauge, just slightly larger than the ones on it before, but for some strange reason the people at Kustom did not have the foresight to consider heavier gauges. On top of that the saddles on the bridge were notched with several small v grooves each, that had sharp edges, and would have easily shredded the nylon windings causing them to unravel.

After calling the owner and approving the extra work I filed out the nut and tailpiece to accommodate the strings, and notched the saddles with smooth and safe rounded grooves, and evened out the string spacing at the same time.

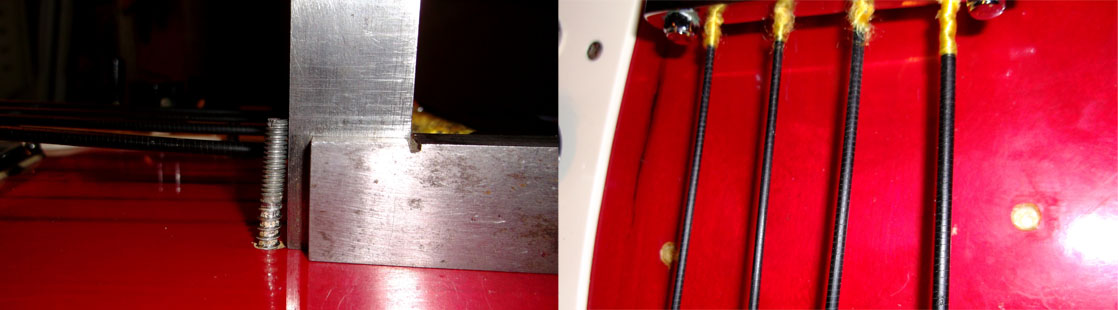

I adjusted the truss rod and bridge height, and started intonating it, and found the strings to be so sharp, that the saddles could not be brought back far enough to compensate them. I had to call the owner again, with more bad news: the bridge had to be moved around 1/4" back. When I removed the huge height adjustment screws from the bridge posts, I could see that someone at Kustom already knew that the holes for the posts were off, because they ramrodded the bridge posts into the top in extreme angles in an effort to fix it! Check this out:

The right side of the picture shows how I closed the holes prior to drilling new ones. In the picture with the new pick guard further up on this page, You can not see the old holes, because the height adjustment screws are 3/4" wide and cover them up.

Final tally:

I set up the bass to have a pretty low action, and intonated it properly. After it was back with the owner for a few days, he wrote in large size and bold font:

"Hey Bob, let me know if you get these pictures. Thanks again for the great job you did on my bass, I love it!!!!! Good luck with your business, I will definitely give your name out every chance I get. Howard"

I had spaced taking pictures after filling the bridge post holes, so I asked if he could send me some. The Body shot with the finished pick guard is from him. Thanks Howard!